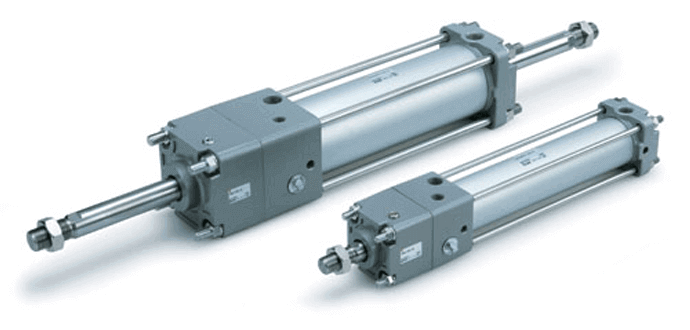

Enhance Machine Safety with Locking Cylinders

Stopping a pneumatic cylinder in emergency situations or during regular operations is essential to machine safety. Although there are many ways to solve this challenging application, stopping the flow of compressed air using an air circuit combined with a mechanical locking cylinder will be the most enhanced level of safety.

The energy in compressed air can be controlled and directed by solenoid valves to produce cylinder motion, but it can also be harnessed to abruptly stop cylinder motion.

The common way to stop cylinder motion is to direct the compressed air through a 3-postion, spring return, center closed solenoid valve to trap the pressurized air on both sides of a cylinder in an e-stop situation. When electrical power is interrupted purposefully (e-stop) or accidentally, the spring return function will position the valve back to the center, trapping the pressurized air, thus halting all pneumatic motion.

Although stopping a cylinder with a pneumatic circuit can be highly effective, this method alone is not recommended for maintaining the cylinder in its stopped position, especially when it is bearing a heavy vertical load.